Timing belts last 60,000 to 100,000 miles. check your owner's manual for the manufacturer's replacement interval.

Your six-year-old econobox is starting to show a bit of wear and tear, but everything mechanical still works fine. Until it doesn't. Specifically, the engine suddenly goes dead silent one fine day. Your mechanic says your timing belt failed, then he chuckles into his shirt pocket. Now he gets to charge you for the tow, the belt replacement and a valve job, because there's no compression on two cylinders. You're one of the unfortunates with an "interference engine" -- an engine that can leave one or more valves still propped open far enough to contact a piston when the belt parts. Sadly, sales brochures don't list whether an engine might suffer catastrophic damage if the belt goes.

You probably could have avoided this particular bit of unpleasantness with timely maintenance. It's best to replace the timing belt according to your carmaker's recommended schedule. For the record, many engines -- like those in more expensive models -- still use timing chains, rather than belts, like they did back in the day before the popularity of overhead camshafts. Unlike belts, timing chains usually don't have a routine replacement interval.

The timing belt (or chain) is the sole component that keeps the camshaft (make that camshafts on a DOHC or V-type OHC engine) and crankshaft in sync. So replacing this cogged reinforced-rubber belt at regular intervals -- generally every 60,000 miles unless the car manufacturer specifies longer -- is a lot less expensive and aggravating than having it break first. For your car's maintenance schedule, consult the owner's manual, alldata.com, or the belt manufacturer's poster hanging on the wall at your favorite parts store.

Slow but Steady

Though you'll spend only a few minutes replacing the timing belt itself, it can take an hour or more to dig down through the spaghetti of hoses, wiring and covers found in a modern engine bay. We even had to disconnect and cap a pair of fuel lines when we did the job on this VW 2.0-liter Four.

Study the procedure before digging in, either in a service manual or on the Web. On most transverse four-cylinder engines, you'll have to remove the passenger-side motor mount in order to gain access to the timing belt. This means the entire powertrain needs to be supported in that area while you're working. And finally, getting to the lower portion of multipiece timing belt covers usually requires underbody access. A fender cover doesn't hurt either, to protect the paint from your belt buckle and dropped tools.

border="0" cellpadding="0" cellspacing="0" style="border:thin solid #cccccc;">

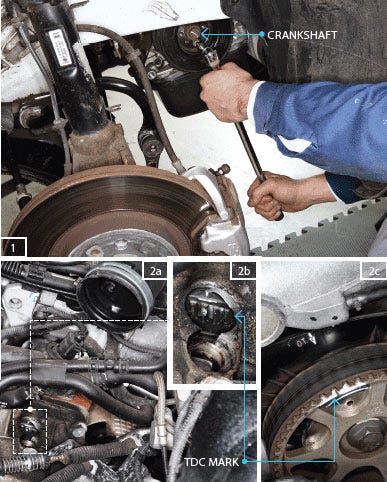

(1) Remove any shrouding in the wheel well so you can access the crankshaft snout and the lower timing belt pulley.

(2a) Find the timing marks on the flywheel and cam, and set them both to TDC.

(2b) The flywheel pulley TDC mark is accessible through a hole in the bellhousing.

(2c) The camshaft TDC is easy to find -- especially if you add white paint as we did.

Time and Time Again

We cannot stress this enough: Be careful! Make sure you know where the timing marks are on your engine, and that you have them set up properly with No. 1 cylinder at top dead center (TDC) on the compression stroke before attempting to replace the timing belt.

Why? 1) That interference engine thing again; and 2) Every camshaft and crankshaft on planet Earth is indexed to No. 1 TDC. If you try to remove and replace the timing belt with the engine in any other position, chances are good you'll throw things out of time. Then you'll get confused and have to pull off the valve cover as you try to determine when No. 1's valves are closed (which begins the compression stroke) in order to re-index the engine. Get your marks lined up right the first time.

After you remove the top section of the timing belt cover, you should see a timing mark on the camshaft sprocket -- this mark usually lines up with the edge of the cylinder head or valve cover. For the crankshaft below, there probably will be a timing mark on the damper pulley that lines up with another mark on the lower cover. Or, the service manual may direct you to the transmission end of the engine to look through a hole in the bellhousing for a timing mark on the flywheel. The flywheel is bolted to the other (transmission) end of the crankshaft. On some vehicles, you may find these marks in all three places.

border="0" cellpadding="0" cellspacing="0" style="border:thin solid #cccccc;">

(3) Support the engine with some sort of skyhook if you need to remove the rightside motor mount. Some belts are installed with a mount in their center, making changing them problematic.

(4) The motor mount can now be removed temporarily.

Support and Tension

Of course, there are professional engine-support rigs available for purchase or rent. But as you can see in our photos, some lumber and an adjustable tiedown strap work just fine to support the powertrain while you remove that cumbersome motor mount. Once it's out of the way, though, you're almost home. Just remove the rest of the timing belt cover sections and turn your attention to the tensioner pulley mechanism.

This tensioner may be an automatic hydraulic type that you simply crank in one direction to remove the old timing belt. Or, you may have to loosen the tensioner pulley adjustment bolt to release the tension and the belt. Before proceeding, confirm which way the engine rotates during normal operation. (Pull the fuel pump relay or fuse first if you need to disconnect fuel lines the way we did. Don't ask how we found this out. We're still getting the gasoline smell out of our coveralls.) Knowing which way the engine turns is important for checking the new belt's alignment later; you don't want to be off by a tooth on one of the sprockets. The easiest way is to have a helper bump over the starter motor with the ignition key while you watch the engine. Of course, now you'll have to reset your timing marks by hand. Don't rotate the engine backward to the marks. Crank it around forward to maintain the correct tension and to keep the belt from jumping teeth.

TDC? Now you can carefully slide the old timing belt off its sprockets and pulleys, while trying to keep the camshaft and crankshaft from spinning. With all the timing marks lined up, route the new belt around the largest diameters first, leaving the smallest pulley or sprocket for last. It's tricky to slip the new, stiffer belt over that last one, but you'll get it after a couple of different wiggling, jiggling attempts. Now, make sure the timing marks are still lined up.

Warning: If you know you're working on an interference engine, do not rotate the camshaft or the crankshaft independently while the timing belt is off the engine. You could cause the pistons to hit the valves, or vice versa, and cause the same damage as if the timing belt had snapped with the engine running -- bent valves!

If you're working with a manual tensioner pulley setup, now is when you perform the factory procedure to tighten the new belt. A hydraulic tensioner takes care of this for you. Once the tension's set, place a socket on the big nut holding the front pulley on and use it to turn the engine over -- two complete crankshaft revolutions in the direction of normal rotation. Line up all the timing marks again. Everything still on the money? Then you've finished replacing the timing belt -- but you have another hour's work to reinstall the cam belt covers, any shrouding, and all the wires, engine accessories and hoses you moved or removed.

border="0" cellpadding="0" cellspacing="0" style="border:thin solid #cccccc;">

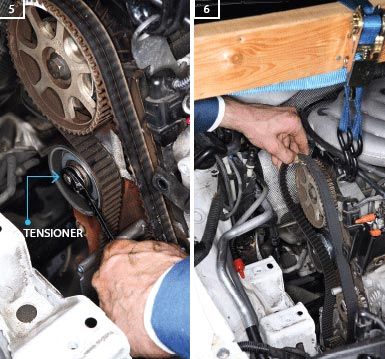

(5) Release any belt tension by freeing up the belt tensioner pulley.

(6) Slip the new belt into place without disturbing the cam or crank pulleys, or the engine will be out of time. Check by slowly rotating the crank two full turns with a socket on the crank snout.

This content is created and maintained by a third party, and imported onto this page to help users provide their email addresses. You may be able to find more information about this and similar content at piano.io

Posted by: jeromyjeromystephsone0272393.blogspot.com

Source: https://www.popularmechanics.com/cars/how-to/a1425/4212995/

0 Comments